Handling multiple variables at once in engineering often requires successive iterations before concluding cause effect relations. In this article they will be named and treated separately, with a short description and eventually in the best case, an order of magnitude of the benefit that adopting each of the options considered suitable supposes in modern precast.

Obviously, the starting point when dealing with the production of hollow core slabs is the concrete used. The machines of mechanical casting work with a zero-cone concrete, while the in the flow casting it is sought to obtain a degree of plasticity on the concrete using advances in the plasticizers and water reducers available in concrete industry.

Geometry

It is surprising to see how the `Gosudartsvenny Standards’ still read hollow core spans in fix increment steps of 600 mm, or in Uzbekistan most of the slabs used at the sites are of thicknesses 220 mm. and 300 mm. and yet the users are still having to deal with and accept certain limitations referred to the geometry of the pre-stressed concrete elements.

Geometry

WIDTH OF THE SLABS

At the final stage in the production of hollow core slabs, they are cut to specific span lengths. The most frequently used width is 1,2 m although in certain Eastern Europe countries the 1,5 m. width is used as well. For thicknesses of up to 300 mm. it is also possible to produce them 2,4 m. wide would the elevation means and the safety working conditions allow it.

However, the floors might not be sized as a multiple of 1,2 m. in which case a small shuttering is provided to finalize with in-situ concrete, or a longitudinal cut is made on a standard slab to fill the gap.

The production of 1,2 m. wide slabs to cut them on their full length to obtain a smaller width, means a loss of material with added value, since the slab is already finished. Therefore, the cost of the fabrication waste is not only associated to the loss of materials but also to the labor, and the crushing and steel separation tasks.

When the plastic concrete flows through a static mold, the fractional width is obtained reducing the number of cores or modifying the thickness of the removable mold sides for a fine adjustment. This method avoids the production waste.

THICKNESS OF THE HOLLOW CORE SLAB

In the same way that any length or width of hollow core slab can be obtained, it is also possible to cast them in any thickness.

Nowadays, when the thickness of the necessary slab is not available on the pre-caster’s catalogue, the next superior thickness must be often used, which results in additional weight of the structure with the related increase of its inertia.

In projects involving a big carpet area, a dedicated mold of specific thickness is justified, and its cost easily balanced by the materials saving.

NUMBER AND SHAPE OF THE CORES

Both the flow formers and the mechanical casting machines have a restricted width due to the size of the production beds. However, in the second case, the mechanisms necessary to the production with a given number of cores are confined within a limited available space. The higher the number of cores, the more transmission elements and driving units are required.

A flow of plastic concrete can be shaped with the number of cores of the customer’s preferences and according to the codes, from 80 mm. to 600 mm.

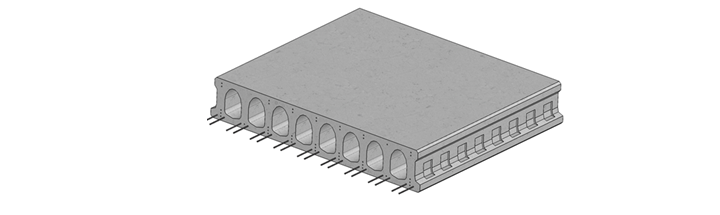

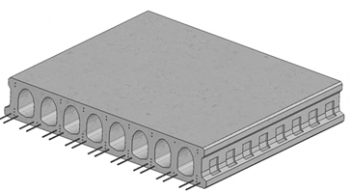

Figure : different shapes of the cores

Less circular cores as big as possible doesn’t necessarily mean less weight per square meter of hollow core slab.

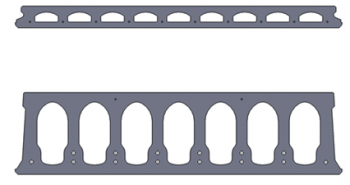

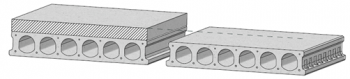

Figure.: Different number of cores for the same slab thickness.

The number of cores is influential in the shear capacity of the slabs, the strand patterns, and their assembly mode

STRAND PATTERNS

The number and shape of the cores result in the available space to place the pre-stressed strands or wires. The higher the number of cores, more theoretical positions to place the steel, while the concrete cover distances are respected.

In the following figure, in the slab with 6 cores it is possible to place 3 additional strands compared with the 4 cores design and with a more uniform distribution across the section.

Consequently, a bigger number of strands results in a higher bending moment capacity for the same slab thickness.

Such strand distribution is favorable when the slabs are cut at the end of the production process because it avoids the pre-stressing concentration in certain spots which could cause the shearing of the slab; this is called the ‘spalling’ effect.

Another way of avoiding this inconvenient with heavily reinforced pre-stressed slabs, is the production of the slabs with a track of exposed wires at both ends. See ‘Building Method’.

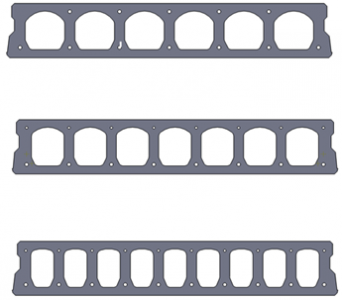

Figure.: #19 cables distributed in 7 positions, or #16 cables distributed in 5.

Building system

The pre-stressed concrete hollow core slabs can participate in different ways in the building method, provided they are produced with certain characteristics.

EXPOSED WIRES

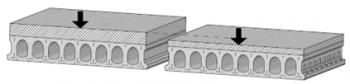

Instead of cutting the concrete slabs according to preset spans, they are produced with the strands protruding a fix distance from both ends.

During the fabrication, the concrete is held upstream the mold while the casting machine keeps on moving forward. A track of exposed wires without concrete is then obtained with a length and position set by the machine automation.

In this production modality, with the ‘exposed wires’ operation mode enabled, the concrete cutting machine is no longer required. The slabs are cut easily at the exposed wires so that half of the track belong to each of the two consecutive slabs.

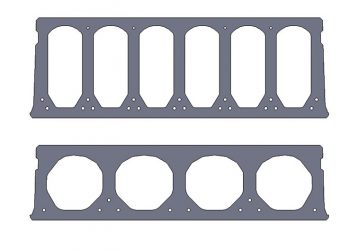

Figure: Hollow core slab with exposed wires at both ends

The behaviour of the slabs produced with tracks of exposed wires with regard the rest of the building structure and to the supporting beams is as follows:

- The slabs may be designed with additional pre-stressed steel across the section without being affected by the spalling effect the cut happens at the track without concrete.

- The track of exposed wires protruding at the end of the slabs work in dowel action with the grout pored at the joint and the loops of the supporting beams.

- The exposed wires then work avoiding the tension across the longitudinal joint between adjacent slabs, this is collaborating in the membrane function of the hollow core slabs on a floor.

Furthermore, the lines of exposed wires help to a partial restraining of the slab, which avoids the torsion with respect to the slab’s central longitudinal axis. Therefore, the stresses and vibrations are not transmitted, favoring the integrity of the joint during the life of the building.

The production of slabs with exposed wires has an advantage when comparing with the use of reinforced concrete filigree slabs, since they do not require reinforcement bars or a grid band across the joint, which is an intensive labor task.

SIDE INDENTING

Both the mechanical molding and the concrete flow casting machines produce the hollow core slabs with smooth surfaces, according to the terminology of the Eurocode 2. At the factories, the slabs’ top surface is scratched so that the concrete topping attaches well and it is really working in composite action with the slabs in the presence of a utilization load.

However, the slabs may increase the capacity to generate additional friction between them and the concrete added at the longitudinal joint, this is between concretes cast at different times, provided the surface interface gathers certain characteristics. Most of the international codes deal with the friction at the concrete surfaces.

The American ACI318 distinguishes between smooth surfaces and intentionally roughened, provided there is 1/4″ from peak to valley. In this case, there is a mechanism for the transmisión of additional shear

The Eurocode 2 about concrete structures is not using the term roughness but the indenting and it defines its geometry in the pragraph 6.2.5.

Another chapter of the same code, 10.9.3 (12) indicates that if the slab concrete surface is smooth the friction between slabs and concrete at the joint must be limited to 0,15 N/mm2 .

Note: as order of magnitude, an indented surface even without compression forces across the joint, develops an average friction of up to around three times this value.

(See for example: ‘Precast Concrete Structures, 2nd Edition published by IPHA). The European Norm EN1168 about the design of the concrete elements mentions specifically the side indenting in the Annexes when states that in seismic zones the hollow core slabs must have a side indenting or in its absence a concrete topping of at least 40 mm. with steel grid must be laid on the top.

Else, the Joint Research Center also mentions the side indenting on the slabs to increase the friction at the joint; see the EUR JRC37588 document

Some countries have decided building the floors with hollow core slabs without topping. The friction generated by a topping of a certain thickness is given by the general equation

Vc = bw * d * fv Provided the side indenting creates an additional friction at the longitudinal joint equal or bigger than the friction developed by the concrete topping, and the live loads are uniformly distributed, the topping may be removed.

TOP MARKING OF THE HOLLOW CORE SLABS

The definition of indented surface is not applying to the sides of the slabs only, but to the top surface as well.

CONNECTION OF HOLLOW CORE SLABS IN CONTINUITY

Regarding their assembly, the hollow core slabs can be placed simply supported or with the ends restrained.

The Bulletin 6 of the Federation International of Concrete (fib – Lausanne, Switzerland) treats the connections for continuity and the negative bending moments. In the conclusions, they find the hollow core slabs with higher number of cores have higher bending moment and shear capacities.

CONCLUSION

The decision on the utilization of plastic or zero cone concrete in the production of hollow core slabs and other pre-stressed concrete elements, must be made taking in consideration all the variables affecting the production cost in comparable value units.