For more than 50 years Prensoland has been developing and manufacturing TENSYLAND beam-casting machines for the production of prefabricated concrete materials, allowing the automated manufacturing of different kinds of products such as beams, slabs, hollow-core slabs, hollow slabs, shuttering slabs, lintels, posts, etc. Tensyland beam-casting or moulding machines stand out due to their great versatility, minimum maintenance, ease of use and quality of the final product. Below are the main advantages of this equipment.

Complete versatility in the manufacturing range

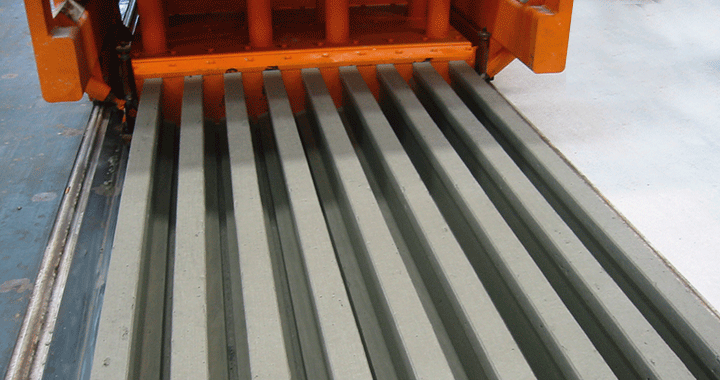

Thanks to a simple tuning mould change, these beam-casting machines manufacture different types of products and profiles, such as single and double “T” beams, tubular beams, solid slabs, hollow slabs, lintels, posts, etc. This change of mould, using a quick plug system (without bolts), can be carried out in about 5 minutes.

Manufacturing the item integrally

The product is cast in a single phase, ensuring that the entire area has the same density, quality and texture of concrete. This feature prevents poor adhesion, fissures or cracks resulting from a manufacturing process in superimposed layers. In beam profiles the whole perimeter has a perfect finish, as do hollow slabs, whose upper surface is completely flat (without undulations) and perimeter cavities that are non-deformable.

Manufacture of iHCS side marking, top marking and revealed wires

The TENSYLAND beam-casting machine makes it possible to manufacture items with revealed wires, a top “carantage” marking system and slabs with iHCS side marking, essential options in seismic risk areas.

Minimum maintenance and virtually zero wear

The design of the TENSYLAND beam-casting machine and its system of operation, without moving parts, ensures minimal maintenance with low annual cost, as well as practically zero mould wear.

Patented mould tuning system. Constructed in 2 parts – one rigid, and the other tilting.

The final part of the mould is insulated from vibrations and allows for a controlled loosening of the concrete. It improves the precision of the manufactured part significantly, saving concrete costs and ensuring a more consistent quality.

Significant electrical energy savings

Total power installed in TENSYLAND beam-casting machine = 17 kW.

Great density and compacting of the concrete

Uniform density and compacting to the whole concrete core, creating a perfect enclosing for the pre-stressed cables and completely preventing these from slipping as a result of poor adhesion.

Simplicity in operating the machine

A single operator is sufficient. The cleaning process is extremely easy, without needing to dismantle any element.

High manufacturing speed

of up to 3 metres/min.